Circles

Note that circles is a hard problem on CNC machines, especially using the GRBL postprocessor, see links at the bottom of this page.

Location:

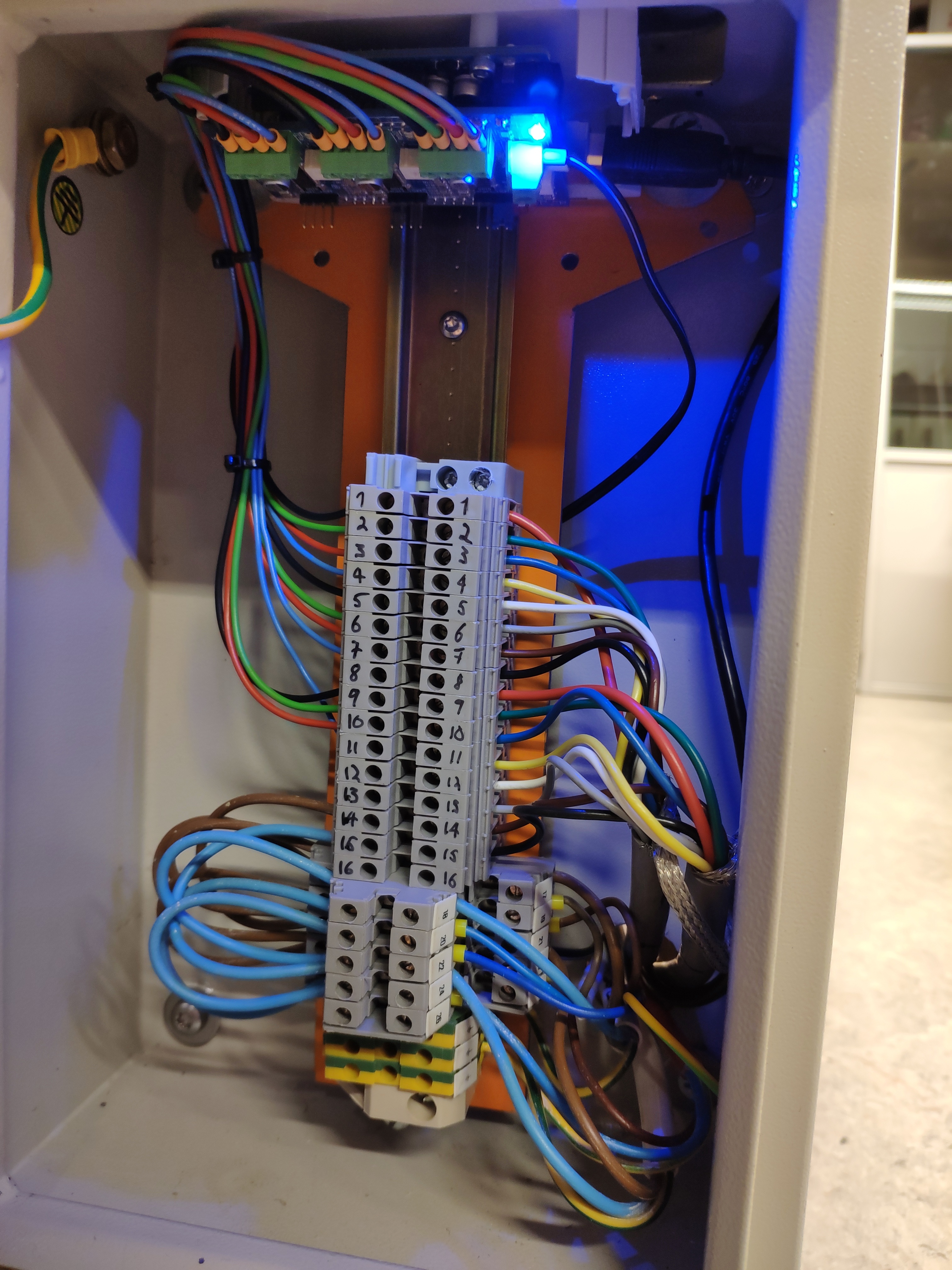

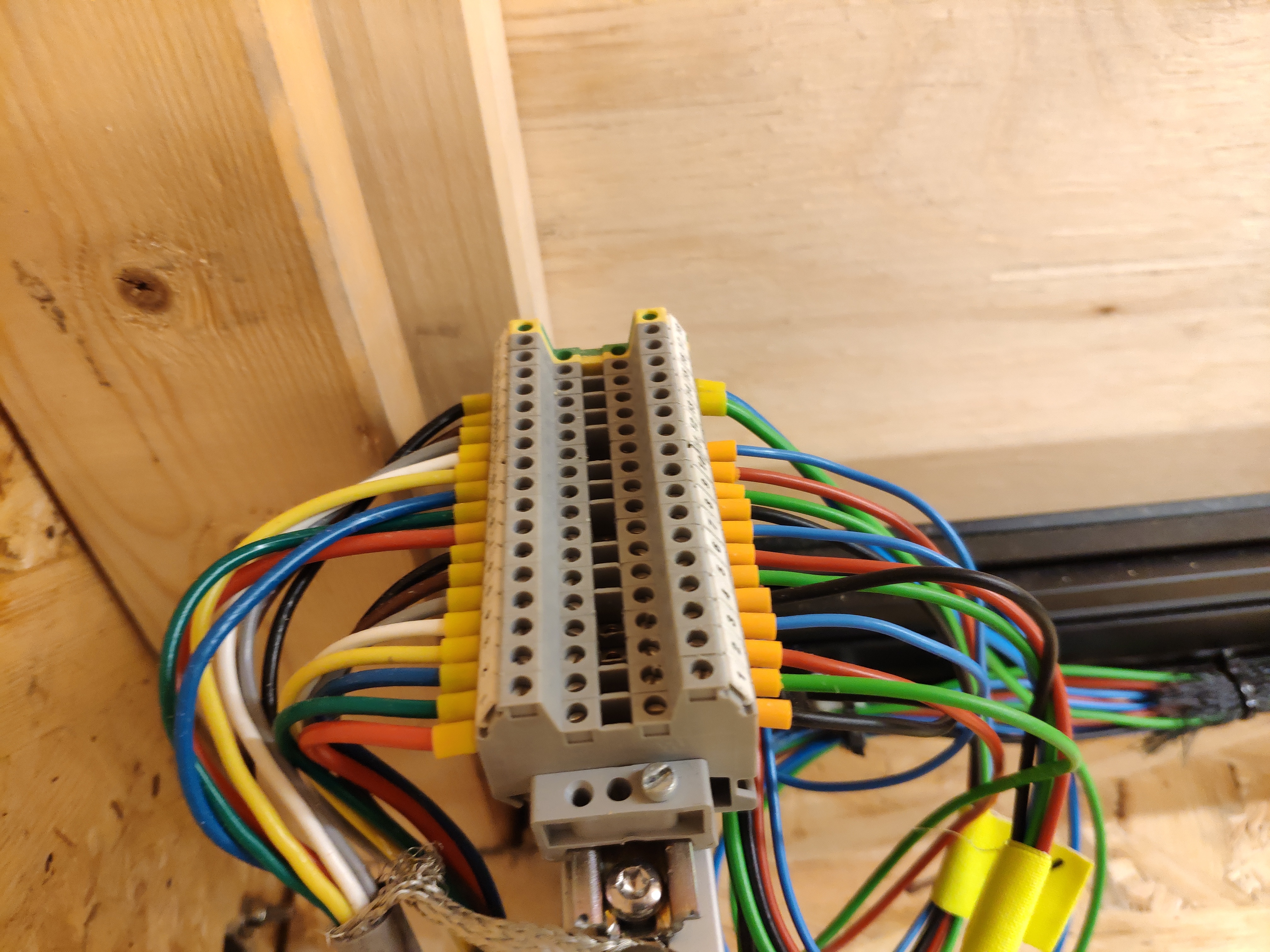

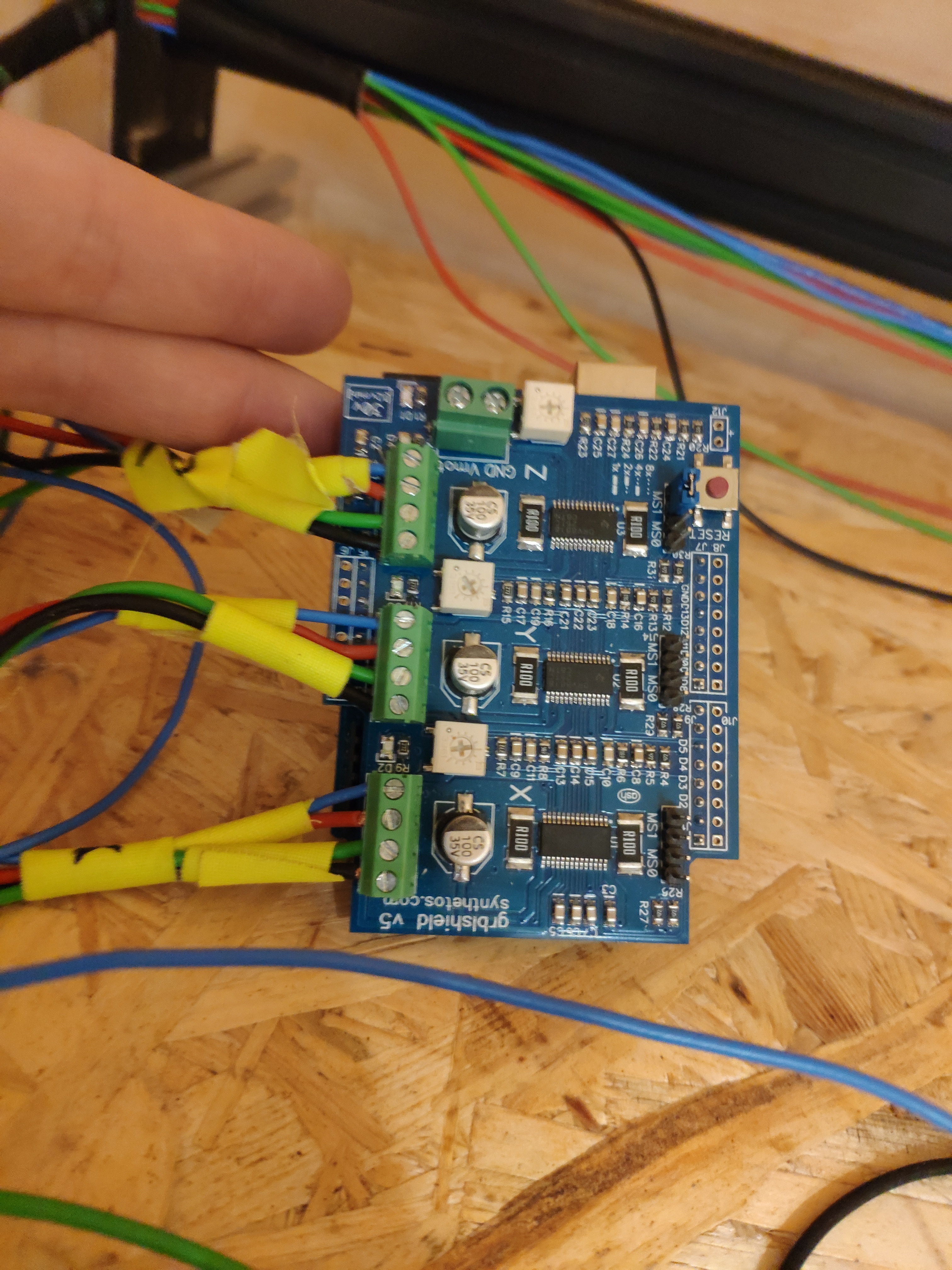

In EL0, under the soldering oven. Controlled by inquisition.ed.ntnu.no

Specifications:

The machines outer dimensions are 740x1500mm.

How to use

- Draw your design in CAD software. i.e. Fusion360

- Create toolpaths including feed rate, depth of cut in CAM software i.e. Fusion360

- Export the toolpaths from the CAM software as gcode using GRBL postprocessor.

- Check that the cut bed is clear of clutter.

- Mount your material to the cut bed with wood screws.

- Turn on the router by switching on the "Main switch"

- Change to the desired endmill.

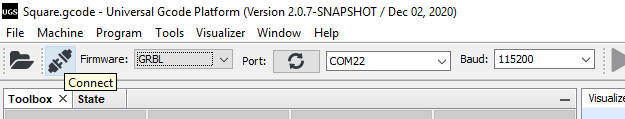

- Start the software (UGSPlatform) on the computer (inquisition)

- Connect to the CNC controller by pressing "Connect"

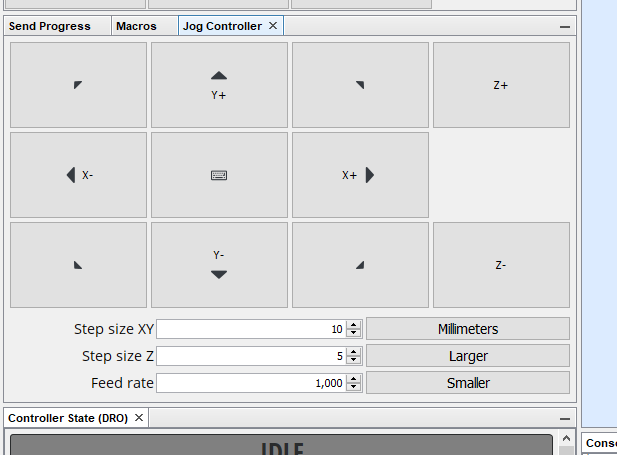

- Jog the router to the desired starting position

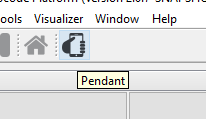

- It is also possible to use your mobile phone as a pendant

- It is also possible to use your mobile phone as a pendant

- Zero the Z axis by jogging 1mm at a time until you are 1mm off the surface, place a piece of paper underneath the endmill, then jog 0.1mm at a time, moving the paper under the endmill, and stop when the paper is barely caught under the endmill.

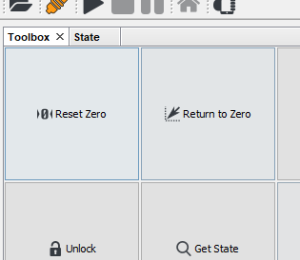

- Press "Reset Zero"

- Jog at least 5mm up from the surface.

- Load the gcode file you prepared earlier

- Set the spindle speed by setting the wheel on the spindle

- Press the green "Power on" to start the spindle

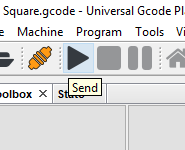

- Press "Send" in UGS

- Observe the cutting, press stop or turn off the main switch if something goes wrong.

Cut bed size:

Circle limitations ref:

https://www.cnczone.com/forums/hobby-discussion/343174-cnc.html

https://github.com/grbl/grbl/issues/966

https://forum.shapeoko.com/viewtopic.php?t=8239